Microwave Imaging (MWI) Technology

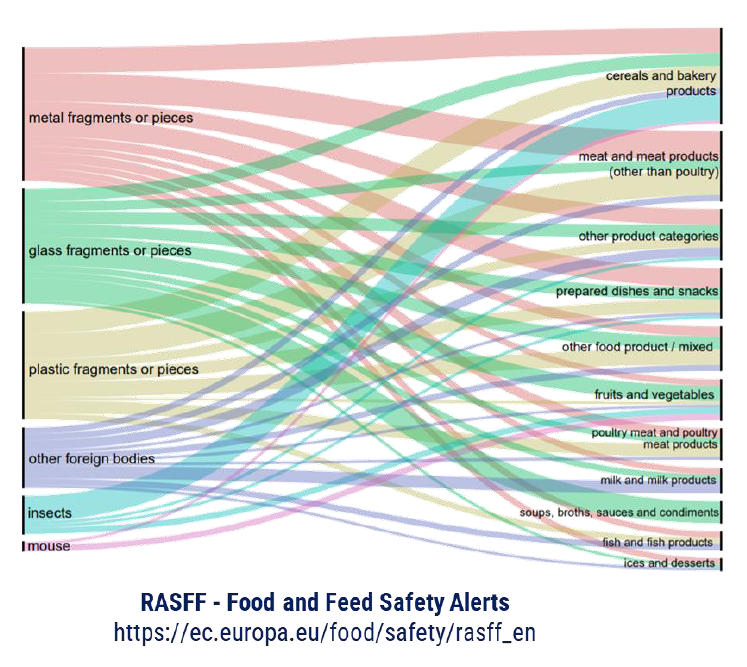

The project aims to complement the lacks in quality and safety inspection devices. It has been thought to overcome the intrinsic limitation of existing techniques in industries quality assurance and non-destructive testing; X-rays based devices for example, are not capable of detecting low-density contaminants, given their detection principle. While metal-detector can recognize conductive materials only. As a matter of fact, the alluvial graph below confirms this issue: it collects a part of food recall from all over Europe and demonstrates that physical contamination is still an open issue.

MWI detection principle

Our approach works on a different and innovative principle, the dielectric contrast between the medium to inspect and the potential intrusion. Even if really low, the alteration of microwave signals due to the presence of contamination, in contrast with the content to inspect, is the novel principle on which our technology is based.

An antennas array surrounds the item to inspect along a production line; microwave signals penetrate the object under test and monitor the potential presence of a foreign body through an alteration from an expected behavior. The operating frequency of the low-power and safe microwave emissions is set up according to the dielectric features of the product to inspect: a trade-off between penetration depth and resolution is chosen, in a range from 2 GHz to 12 GHz.

The architecture and the position of the sensors in the system is properly defined, considering the shape of the object and optimizing the spatial coverage given by the sensors.

Prototype development and results

The realized prototype is designed to be integrated into existing production lines, requiring minimal adaptation. The device can work real-time, acquiring the needed signals while the products are moving at production speed, so without interrupting or delaying the processes. The signal processing as well has no latency, giving a binary output in the order of milliseconds.

A calibration phase is foreseen for each kind of product to inspect, so that a neural network classifying and detecting the contaminated samples gets properly trained.

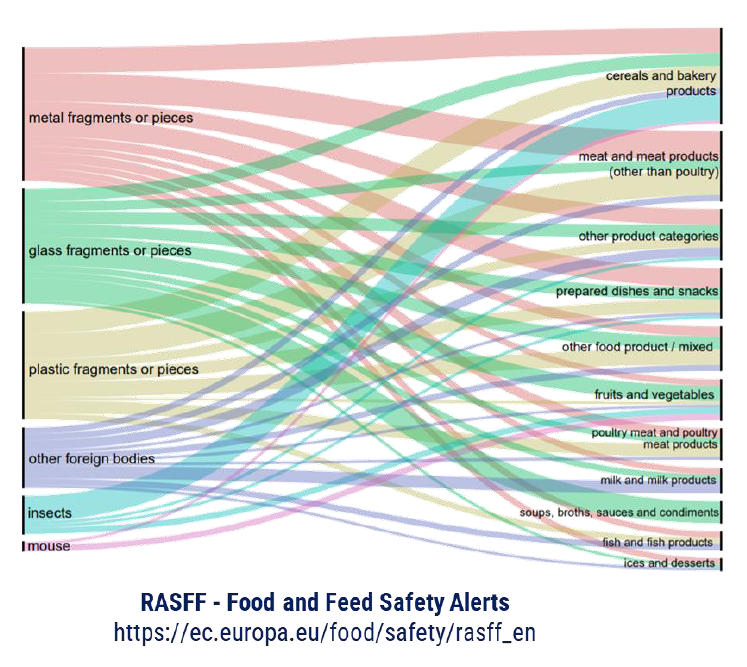

The prototype has been tested and assessed in an industrial environment, monitoring hazelnut-cocoa cream jars and correctly identifying millimetric-sized contaminants (Figure 2).

A pattern recognition neural network has been trained and tested with the performed measurements, allowing to obtain a 100% successful classification of both ‘clean’ and contaminated samples (Figure 3).

Additional features in the prototype are under development, in a way that with proper hardware and programming resources, a tomographic image of the target is carried out, as 3-D mapping of the dielectric composition of the item under test.

Improvements of the algorithms to detect contamination are ongoing as well.

Further reading:

• Ricci, M., Stitic, B., Urbinati, L., Guglielmo, G. D., Vasquez, J. A. T., Carloni, L. P., . . . Casu, M. R. (2021). Machine-learning-based microwave sensing: A case study for the food industry. IEEE Journal on Emerging and Selected Topics in Circuits and Systems, 11(3), 503-514. doi:10.1109/JETCAS.2021.3097699

• M. Ricci et. al., Multi-Antenna System for In-Line Food Imaging at Microwave Frequencies, accepted for IEEE Transactions on Antennas & Propagation

• Tobon Vasquez, J. A., Scapaticci, R., Turvani, G., Ricci, M., Farina, L., Litman, A., Casu M. R., Crocco L., Vipiana, F. (2020). Noninvasive inline food inspection via microwave imaging technology: An application example in the food industry. IEEE Antennas and Propagation Magazine, 62(5), 18-32. doi:10.1109/MAP.2020.3012898

Latest Articles

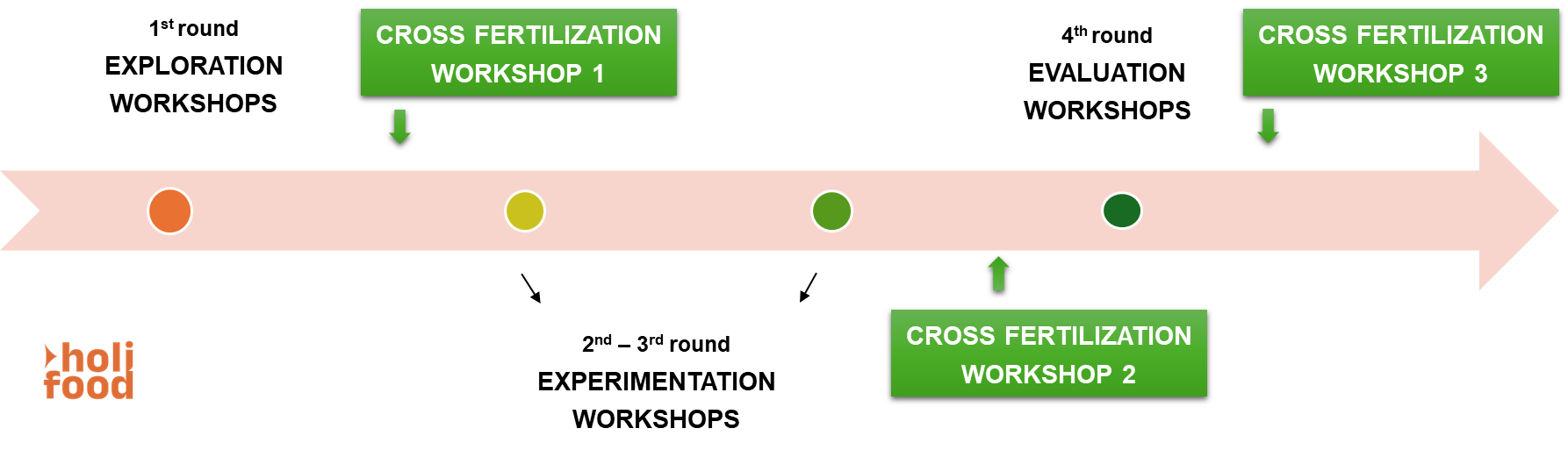

Towards holistic, AI-driven emerging risk assessment: catching stakeholders’ needs in Living Labs

Protecting public health: understanding the importance of cumulative risk assessment of pesticides

SCAR consultation workshop on Sustainable Food Systems: highlights from EU FOOD SAFETY PLATFORM

Pioneering advances in the EU Food Safety System: highlights from the first EU Food Safety Forum

Food4Future_cz

New Tools for Preventing Harmful Bacteria in Ready-to-Eat Foods